Limestone Cleaning Walton on Thames

Discover The Best Limestone Cleaning Walton on Thames

- You are at the best site if you are trying to find Limestone cleaning.

- Our qualified professionals have been reconditioning Limestone floors in the Walton on Thames location upwards of 2 decades..

- Our Limestone cleaning industry experts in New Malden are right here to assist and provide you with a price and timescale to clean your Limestone floor.

Just How Do Professionals Go About Cleaning A Limestone Floors In Walton on Thames

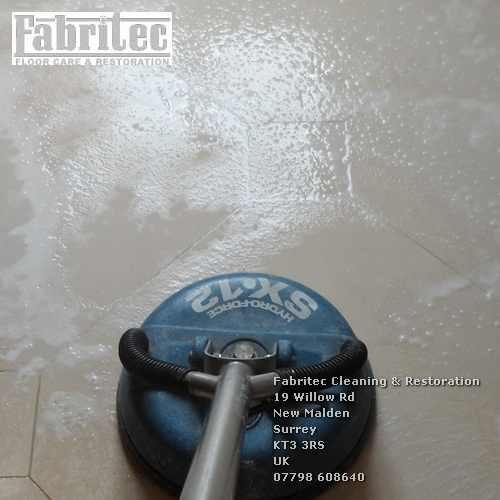

- Specailists set out by putting on a Limestone floor cleaning on the Limestone. Then leave the cleaner for upto 20 minutes to allow the cleaner to emulsify the soil. We also use a scrubing machine to scrub the cleaning solutions deep into the Limestone.

- After the scrubbing stage, they rinse off the slurry and verify the state of the floor. We scub the floor again until the floor has released all the soil it can. With honed and polished Limestone floors, a single scrubbing and rinsing step is usually sufficient to clean out any dirt. Having said that, with Tumbled Limestone and Brushed Limestone tiles, the cleaning might need to be frepeated.

- After scrubbing, there may be soil trapped in the surface of Brushed and Tumbled Limestone, and the grout.

- If there is still embedded dirt after scrubbing, we have hot pressure rinsing machinery. Hot pressurised rinsing forces hot water deep inside the holes and pores in the Limestone and the grout, to get at the dirt that a floor scruber could not reach. It is frequently remarkable how more soil the hot pressure rinsing process extracts.

- Pressure rinsing may possibly not be suited to soft or very porous Limestone, as it can certainly leave a shadow effect with the rinsing..

How Is Limestone Polished?

Limestone polishing is necessary as soon as the shine has worn off the polished Limestone through wear and etch damage.

Limestone polishing begins using diamond honing equipment to clear away the surface imperfections and prepare the floor for polishing.

Fine diamond tooling creates a honed or sheen appearance. If you prefer a high , after the diamond polishing, we use Limestone polishing compound to provide a polished shine.

Limestone Floor Restoration

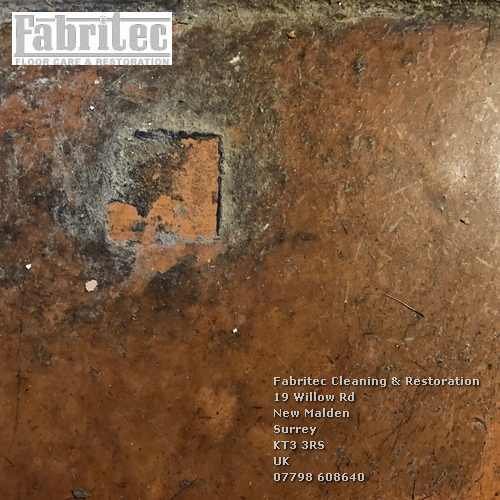

Limestone restoration commences by examining the Limestone for any issues. Typically using powerful detergents and also foot traffic damages the surface on Limestone.

The effect is a scored, permeable finish with tiny, dirt-attracting holes. At these times, the original finish is removed by grinding and honing.

This procedure is known as restoraion. We have a variety of Limestone floor restoration products such as; diamonds for grinding and honing, resin fillers, grout and polishing creams to create a gloss shine.

Wear over older Limestone floors is a result of years, perhaps decades, of being walked on. Laminations in the Limestone can break up, slabs can crack, and the linestone subfloor can move.

This wear is also a reminder of the building’s historic past, it is therefore often preferable to welcome these issues instead of disturb an old floor. Quite often, these aged floors are installed in listed heritage buildings and also any work is rigorously governed via the Heritage authorities.

Call Now for a Free No-Obligation Quotation.

We are trusted  by 100's of clients in Surrey.

by 100's of clients in Surrey.

Take a look at some other stone and tile cleaning and polishing solutions we offer in Walton on Thames , click on the stone link.

Marble Travertine Terrazzo Slate Sandstone Granite Victorian Tiles Terracotta Quarry Tiles Porcelain Tile & GroutLimestone Sealing In Walton on Thames

Sealing Limestone starts out by assessing the type of Limestone in addition to the condition with the floor base.

Sealing A Limestone Floor Not Having A Damp-Proof Membrane

Limestone has been a flooring for thousands of years. Buildings prior to the mid-1950s can have stone floors laid right onto well-rammed soil, chalk or lime-based mortar.

These types of floors want to enable the movement of moisture from the floor base, which has an effect on the selection of the sealer.

These kinds of floors are sealed with an impregnating sealer to keep the movement of moisture.

Applying A Sealer To Polished Limestone

To keep the natural look of polished Limestone, an impregnating sealer is generally applied. One or two coats of impregnating sealer is usually sufficient to stop water soaking into the stone. Polished Limestone tiles should be re-sealed every year to maintain the level of protection. Acid spills will penetrate an impregnating sealer, leaving an etch mark. {Which means that acid spills such as [xfield_acid-spills] will penetrate the impregnating sealer in your Limestone floor, leaving a dull etch mark.} Coloured acid spills will also stain tyour Limestone floor.

Sealing Honed Limestone Floor Tiles

Limestone tiles with a honed finish will have a dull matt or sheen surface. Limestone is much more porous than a polished Limestone, but less permeable than a tumbled Limestone. If you like a natural matt-look, an impregnating sealer retains the first finish. Much like polished Limestone, an impregnating sealer will not stop acid etching.

Honed Limestone can have a film-forming or surface sealer. Just like name of this sealer implies, the sealer forms a protective film the outer lining of the tiles. This protectoive film gives increased protection from damage from acid etching. The protective film acts Since a sacrificial wear surface, absorbing damage from shoe traffic rather than the surface of the tile itself. Since the protective sealer sits on top of the stone, we advise applying an impregnating sealer first. The impregnating sealer helps to protect the stone in places where the surface film wears away.

A surface sealer lasts for two to four years before it needs topping up. We suggest checking wear areas every six months to check for wear. If a place is showing wear, clean areas to take away surface soil, then top the spot up with a couple layers of sealer.

Using this technique, a protective sealer will last for a long time, without suffering from an ugly build-up of protective sealer on parts of the floor that don’t need any more sealer.