Limestone Cleaning Feltham

Presenting Superb Limestone Cleaning Feltham

- If you want Limestone cleaning Feltham as your Limestone floor is ugly, you have arrived at the best spot

- Professional Limestone cleaning in Feltham can quickly return the original finish..

- Our Limestone cleaning industry experts in New Malden are right here to help and give you a cost to clean your Limestone floor.

So How Do We Clean Your Limestone Floors In Feltham

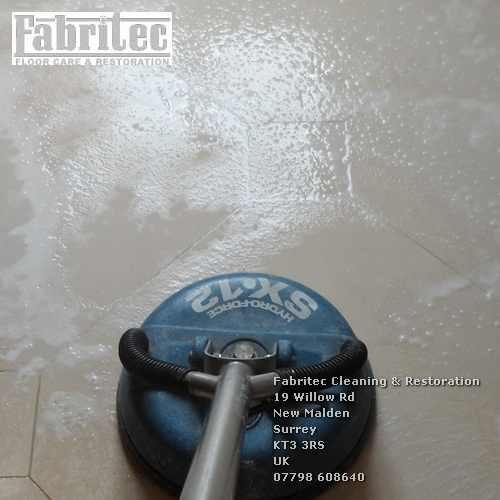

- Specailists start by applying a Limestone cleaning chemical over the Limestone. The cleaner is left to work for about 20 minutes to allow it to break-down the grease laden. We also use scrubbing machines to scrub the cleaning tratment deep into the floor.

- After the scrubbing stage, we vacuum off the cleaning slurry and assess the state of the floor. We scub the floor again until the floor has released all the soil. On honed and polished Limestone floors, a single scrubing step is normally adequate to take off any ingrained sloil. Having said that, with Tumbled Limestone and Brushed Limestone tiles, the scrubbing may require to be repeated several times.

- After machine scrubbing, there can still be soil trapped within the surface of Brushed and Tumbled Limestone, and the grout.

- If there is embedded soil after machine scrubbing, we can make use of hot pressure rinsing equipment. Hot pressurised rinsing drives hot water deep inside the holes and pores in the Limestone and the grout, to access the dirt that the scrubbing machine could not reach. It is frequently surprising how more soil the pressure rinsing equipment removes.

- Pressure rinsing is almost certainly not ideal for soft or very porous Limestone, as it can create a shadow pattern with the cleaning.

Limestone Polishing Feltham

Limestone polishing is needed as soon as the shine has worn off a polished Limestone through wear and etch damage.

Limestone polishing commences using diamond honing equipment to take off any surface imperfections to prepare the Limestone for diamond polishing.

Fine diamond grits produces a honed appearance. If you prefer a gloss, after diamond polishing, we use Limestone polishing powders to give the Limestone a polished shine.

How We Go About Restoring Limestone Floors in Feltham

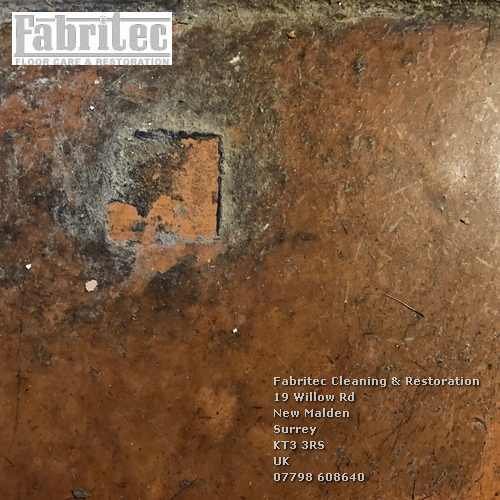

Limestone restoration begins by inspecting the floor for any issues. Typically the use of strong cleaners and shoe traffic degrades the finish on Limestone.

The end result is a scored, permeable finish with minute, holes that attract soil. When this happens, the initial finish is taken off by grinding and honing.

This process is referred to as Limestone restoration. We use different Limestone floor restoration products like; diamonds for grinding and honing, resin fillers, grouts and polishing compounds to produce a gloss finish.

Wear over older Limestone floors is a consequence of many years, perhaps centuries, of footfall. Laminations within the Limestone can splinter, slabs may crack, and also the linestone subfloor cound move.

The wear is a reminder of your building’s history, it is therefore often preferable to acknowledge these imperfections as opposed to disrupt a vintage floor. Quite often, these older floors are installed in listed heritage buildings and any tasks are rigorously regulated via the Heritage authorities.

Call Now for a Free No-Obligation Quotation.

We are trusted  by 100's of clients in Surrey.

by 100's of clients in Surrey.

Discover additional stone cleaning and restoration services we deliver in Feltham , click on the stone link.

Marble Travertine Terrazzo Slate Sandstone Granite Victorian Tiles Terracotta Quarry Tiles Porcelain Tile & GroutLimestone Sealing In Feltham

Limestone sealing starts by determining the type of Limestone additionally the state of the floor base.

Sealing Limestone Floors Lacking A Damp Proof Membrane

Limestone has been used as for thousands of years. Buildings before the mid-1950s have their stone floors installed straight onto compact earth, a chalk base or lime-based mortar.

These kinds of floors want to let the flow of moisture through the sub-floor, which impacts the selection of the sealer.

These kinds of floors should be sealed with an impregnating or penetrating sealer to keep up the free movement of moisture.

Choosing A Sealer For Polished Limestone Tiles

Polished Limestone must be sealed with an impregnating sealer, to protect and keep the natural look of a stone. A polished Limestone needs less sealer than other finishes, so 1 or 2 costs of sealer usually will do. An annual application of sealer helps retain the amount of protection on polished Limestone. Be aware that an impregnating sealer does not restrict acid etching polished Limestone. {Which means that acid spills such as [xfield_acid-spills] will penetrate the impregnating sealer on your Limestone floor, leaving a dull etch mark.} If there is a storing dye when you look at the liquid you spill on the Limestone, e.g. burgandy or merlot wine, the etch mark will additionally be stained with the colour of the spill.

How We Can Seal Honed Limestone Floor Tiles

Limestone tiles with a honed finish will have a matt or sheen finish. The surface is much more porous than a polished Limestone, but less permeable than a tumbled Limestone. If you like a natural matt-look, an impregnating sealer retains the first finish. Much like polished Limestone, an impregnating sealer will not stop acid etching.

Honed Limestone may have a film-forming or surface sealer. Because name implies, the sealer produces a protective film the area of the tiles. The protectoive film gives you extra protection against acid-etching. The film will act Because a sacrificial wear surface, taking damage from shoe traffic as opposed to the surface of the tile itself. Because the sealer is on the surface of the Limestone, we recommend applying a couple of coats of impregnating sealer first. An impregnating sealer helps to protect the stone in areas where the surface film wears away.

A surface sealer can last for two to four years before it requires topping up. We recommend examining wear areas every 6 months to check for wear. If a region is showing wear, clean the spot to clear out any surface soil, then top the spot up with a couple coats of sealer.

Following this method, a floor protective sealer can last for many years, without struggling with an awful accumulation of protective sealer on parts of the floor that don’t need more sealer.